Mining Pumps

Experts in the supply and maintenance of Mining Pumps, contact Prestige Universal Mining Pumps Supply for all your Mining Pump needs.

From Brand New Mining Pumps, Hire or Maintenance of Existing Pumps.

We can assist you at any stage with the best pump solution to suit your requirements.

As a well-established business, P.U.M.P. can react and adapt quickly, able to facilitate your requirements. Mining Pump Supply is more than just a product, the service and ongoing support is just as important to us.

P.U.M.P. Is Dedicated to Premier Mining Pump Services, Offering Products that Are High-Quality.

Combining quality products with a fast turnaround time.

Offering in-house motor rewinding and expert pump repairs and maintenance which involves:

- Stripping down the motor

- Quoting on requirements

- Rebuilding

- Performance Testing

- Packing and delivering out to clients

There is a lot of time spent monitoring mining pumps during the maintenance service which is valuable in increasing the life of the product. Every pump serviced by Prestige Universal Mining Pumps must pass a full test procedure and meet specification requirements before being sent back to site.

The Mining Pump Supply

and Maintenance Specialists

To provide the best service for pump repair and maintenance, you need a specialist who knows the ins and outs of every part of your pump.

We have brought in a highly qualified team from mechanical fitters to electricians and rewind specialists. This ensures our process is efficient and effective.

Maintenance Process Steps

P.U.M.P. place an emphasis on quality control to ensure all pumps that are sent out to site are functioning at 100%.

The process has been refined to create a streamlined approach that offers consistent quality.

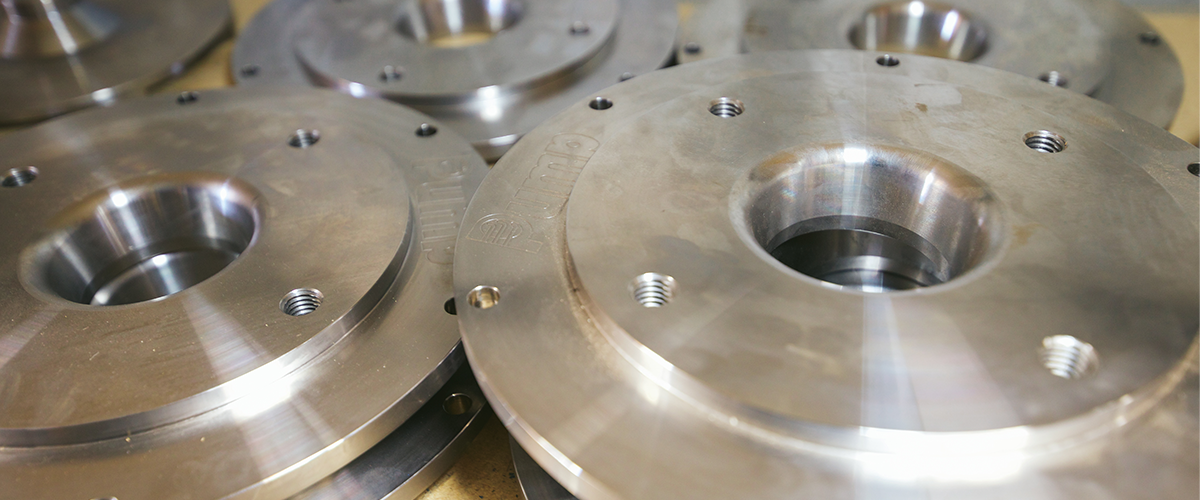

The pump is completely disassembled down to the bare rotor

All individual parts are cleaned and inspected

Any parts that need to be replaced are quoted to the client (beyond serviceable use)

Once approved, a shaft up rebuild is commenced with required new components installed

Testing Process Steps

The testing process is as important as the maintenance process. To be sure that your mining pump is operating at maximum efficiency, Prestige Universal Mining Pumps run rigorous testing to each part of the pump.

Running through a test tank to check it conforms to published test curves, running within electrical parameters and is running in the correct direction

1,000-volt test facility onsite

Electronic Flowmeters to check to the total volume and rate of flow is consistent and between the correct parameters

Electronic Pressure Gauges

Head pressure is applied to the pump during the testing phase to simulate in-service conditions

Once the full testing process has been completed, the pump is painted, packed and sent back to site.

Our Mining Pump Range

Force 5 Pump

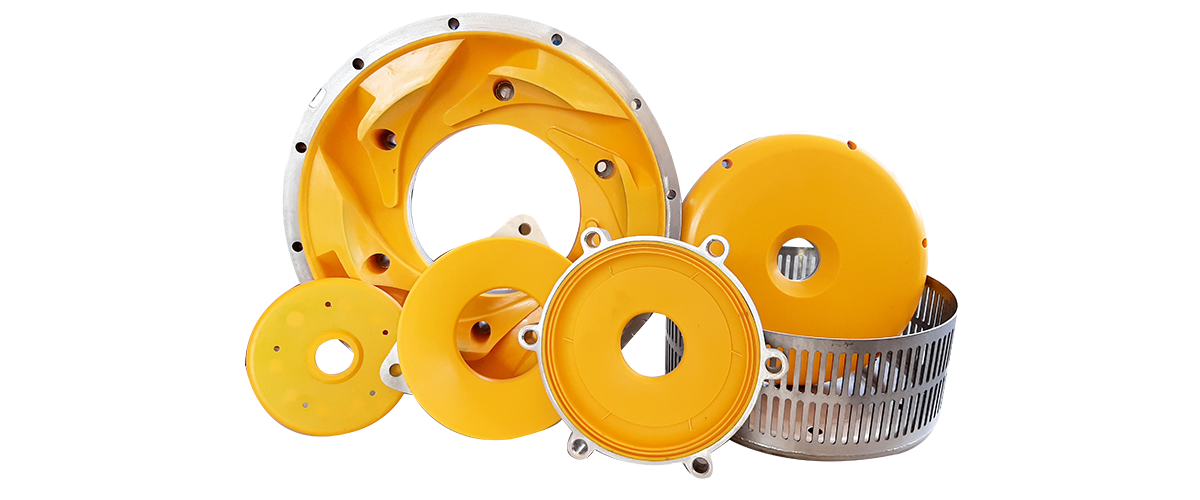

Built for Australian mining projects, this submersible dewatering pump is manufactured using high quality polyurethane, aluminium and stainless steel strainer. It is 55kg in weight, making transportation easy.

Force 8 Pump

Sumbersible dewatering pump designed for versatility and value for money. Its 8kw capacity and 85kg weight supports operational flexibility in mining projects.

Force 15 Pump (Snort Pump)

Snort type mining pump that can be used on underground drill rigs and static pump for sumps. Full repair and servicing included for all Force 15 Pumps.

Force 20 Pump

High capacity submersible dewatering pump. With 20kw in capacity and made to last using materials such as polyurethane, aluminium and pressed steele.

Force 37 Pump

Submersible dewatering pump desgined for efficiency. Its 37kw capacity allows for swift dewatering in the mines. Manufactured in Australia using high quality, durable materials to withstand harsh environments.

Mining Pump Spare Parts &

Repair Services

While mining pump supply and maintenance are at the core of our business, we also provide pump spare parts and repair services.

- Parts

- Pumps (100% our product)

- Also provide pumps/motors/air pumps from leading manufacturers

Frequently Asked Questions

Why are dewatering pumps important for the mining industry?

Dewatering a mining area is crucial to ensure the safety and stability of the mine site. Mining dewatering pumps help to relocate both above and below ground water to allow mining take place. If water is not controlled within areas of a mine site it can holt excavation and the safety of workers can be compromised.

The mining pumps used for dewatering must be robust and efficient in their build and design. This is because they often operate in harsh environments, under heavy workloads. Dewatering pumps are kept on the mine site for the entirety of the excavation to ensure water levels are stable.

What is a submersible dewatering mining pump?

A submersible dewatering mining pump is used in the mining industry for the relocation of water from the mining site to a specified relocation area. Submersible mining pumps are a popular choice for the mining industry because they are hardy, efficient, and can run for long periods of time.

They are effective at dewatering mine sites because they can run whilst submerged in water, meaning their motors are always kept cool and they don’t need to be primed like other pumps. Submersible pumps have the added benefit of being portable and can be relocated to dewater various areas of a mine site.

How do I choose the right pump for the right job?

The type of pump used will depend on the job at hand and what conditions you will be using it in, as well as the environment in which it will be operating in, such as underground or surface dewatering.

The large range of pumps we manufacture ensures we can supply pumps that are well suited to a variety of applications within the industry and are designed for all conditions.

If you mining pump application is unique, we have specific industry mining pump solutions that can cater to your needs.

What do I do when my pump is not performing correctly?

If your pump needs repairs or its not performing as it used to, give us a call and we can run a series of diagnostic tests to determine the issue and ensure your pump gets back to work.

Every pump serviced by Prestige Universal Mining Pumps has to pass a full testing procedure and meet all specification requirements before it is sent back to site. During the maintenance service, a lot of time is spent monitoring mining pumps as this service is a crucial step to increasing the life of the product.

The testing process is just as important as the maintenance process. Prestige Universal Mining Pumps ensures your mining pump operates at maximum efficiency. This is done by rigorously testing each part of the pump to measure its performance and diagnose any damage to parts.

What is motor rewinding and why is it important for your pumps?

Electrical motor rewinding is a process that involves three basic steps: removal or stripping of the winding coils, inserting and connecting new winding coils and insulating the completed winding.

When an electric motor’s performance starts to deteriorate, you must choose to either replace the whole motor entirely or extend the life of the motor with “rewinding’’ techniques.

If you’ve ever been told that your electric motor needs rewinding, it means the coils are damaged in some way such as being shorted or grounded. There are a wide variety of issues associated with motor failures that require rewinding, most of these coming from failed insulation and/or grounded/shortened coils.

Prestige Pumps offers in-house electrical rewinding and pump repairs as well as maintenance which includes:

- Quoting on requirements

- Stripping down the motor

- Rebuilding

- Performance Testing

- Packing and delivering out to clients

We Are Proud to Be Distributors For